Powders – Case Study

Producers in the food and beverage industry use many ingredients, spices, and additives that are in powder form. These powders have a long shelf life, meaning they are often shipped from suppliers around the world to a central processing plant. This also means that monitoring quality of ingredients is a major focus for those in charge of receiving shipments from suppliers. In particular, color needs to be confirmed at each step in the supply chain, since the color of each individual ingredient ultimately translates to the attractiveness of the final product.

For example, a large bakery may be sourcing their flour, sugar, salt, cocoa, and dehydrated milk from a variety of suppliers. Ensuring quality of each ingredient can be a daunting task.

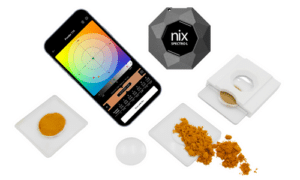

How are Nix spectrophotometers used to measure powders in the baking industry?

1. In communication with suppliers, the head baker decides on the acceptable color characteristics of each ingredient. A sample of each ingredient is measured using the Nix Spectro Liquid & Powder Adapter and entered into the Nix Toolkit app. These master measurements (stored in the L, A, B color space) will be used to confirm that future shipments of powdered ingredients meet the agreed upon color standards.

2. Quality control technicians in receiving are now able to measure a sample of each ingredient as they are delivered to the bakery. Within the Nix Toolkit app, each measurement is compared to the master color and the technician is instantly notified whether the sample falls within the acceptable color specification (this is determined by calculating a simple Delta E value).