Nix color glossary

What is color?

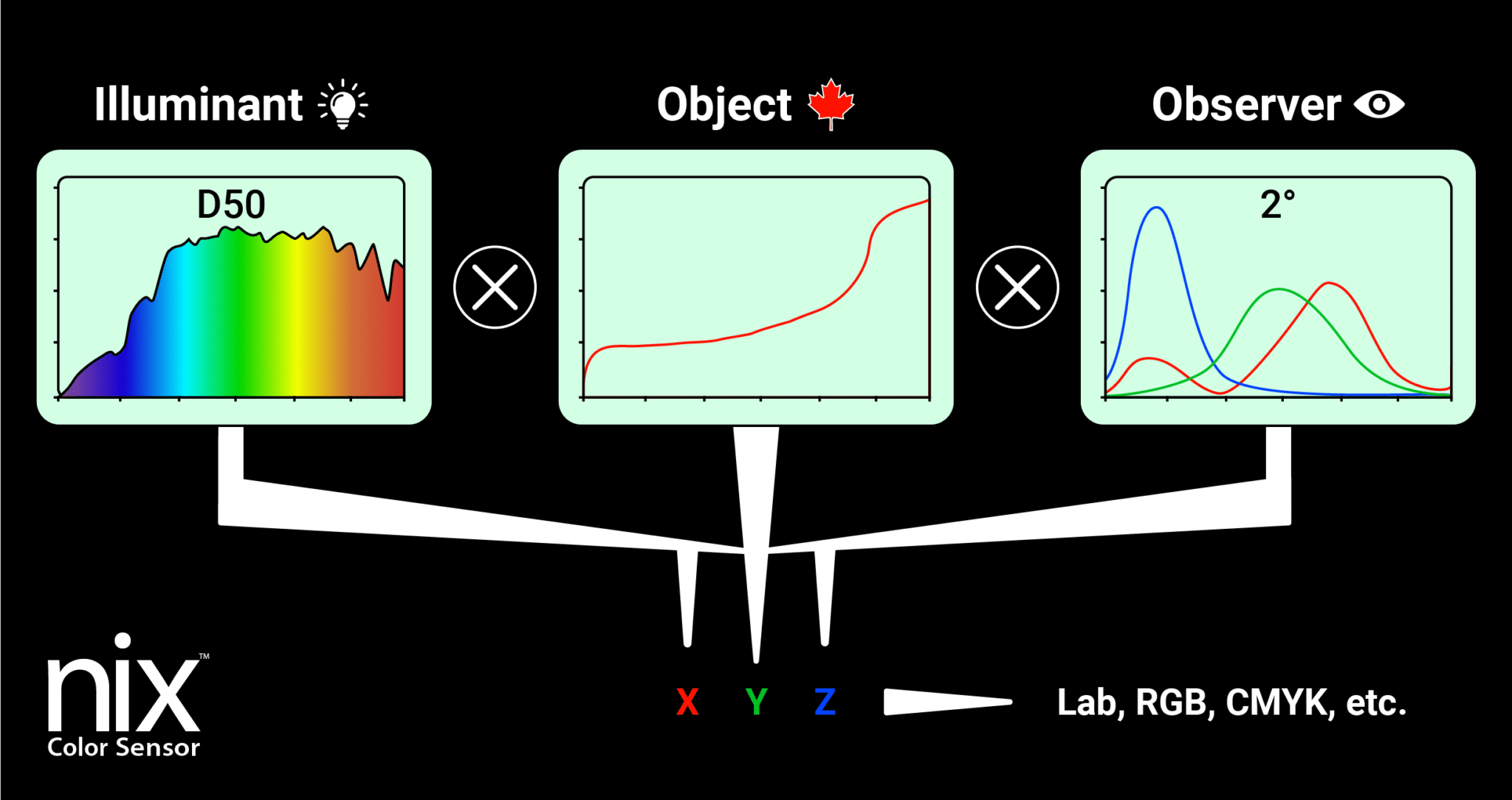

Color is not an innate property of an object. It is a combination of a particular light source (illuminant), the object’s reflective properties, and an observer (human eye, or Nix Color Sensor).

If the illuminant or observer change, the perceived color will also change. For example, a “white” piece of paper in an office looks… white… but if you change the light source in the room to a red light bulb, the paper will now look “red” to you. In the extreme case, if you turn off all the lights (no illuminant), then you wouldn’t experience any color at all (black).

What is not color?

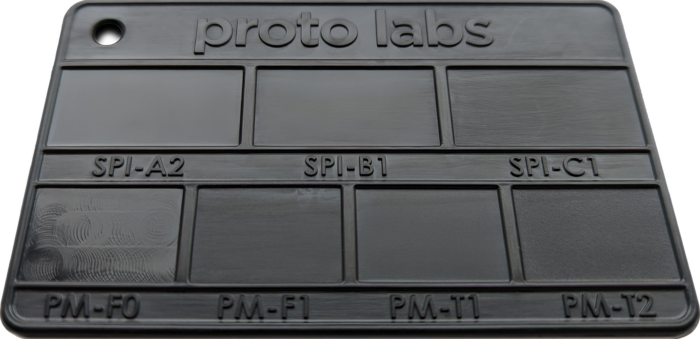

Color is just one aspect of an object’s appearance. Gloss, texture, pattern, material, shape, etc are not color, but can drastically change our perception of an object’s appearance.

Note: This plastic sample is the exact same color across the chip, but the appearance is different depending on the surface texture and the angle the sample is viewed.

Why you need a hardware device

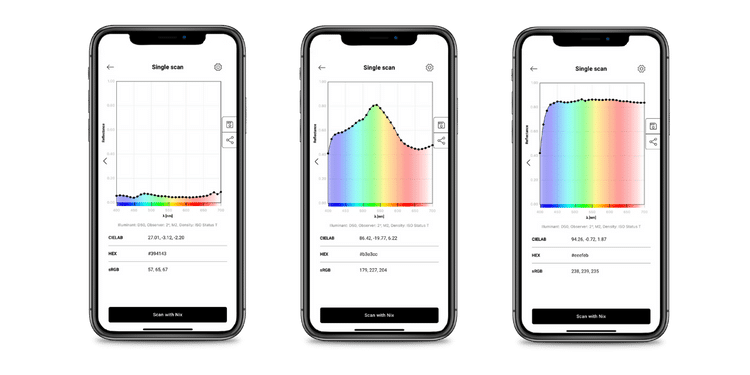

You can’t use your eyes, or a cell phone camera to measure the color of an object objectively:

- Ambient light must be 100% controlled

- The specific illuminant must be 100% controlled and calibrated

- The sensor must be exactly the right distance and angle from the surface being measured and highly calibrated

Even the most high-end cameras cannot take into account the ambient light in a room.

Note: Look around you right now… although the room is painted the exact same “color” everywhere, the corners of the room look drastically different. The Nix hardware solves this problem and can be used in any lighting condition, from bright sun to complete darkness.

General color terminology

CIE: The International Commission on Illumination, abbreviated CIE by its French name Commission internationale de l’éclairage. This international authority defines standards for light, illumination, color, and color spaces.

CMC: The Color Measurement Committee of the Society of Dyers and Colorists, abbreviated CMC. The CMC is an international professional society specializing in color.

Visible spectrum: The portion of the electromagnetic spectrum visible to the human eye. Typically reported from 400nm – 700nm.

Colorimeter: A color measurement device typically used in production, inspection and color-matching environments. A “tristimulus colorimeter” uses 3 sensors representing the CIE XYZ functions. Intended to measure similar to the sensitivity of the 3 cone cells in the human eye.

Spectrophotometer: A color measurement device typically used in high-precision analysis, lab work, R&D, or custom color formulation applications. A spectrophotometer measures the actual spectrum that produces color at discrete wavelengths. Typically for high-end instruments, every 10nm or 31 discrete points from 400nm-700nm.

Densitometer: A densitometer measures ink density. Density is used to calibrate printers for specific inks and paper combinations.

Color Gamut: Is the range of colors that can be reproduced by an imaging system. Some systems may have significantly larger or smaller color gamuts, depending on many factors.

Device-dependent color model: A color model where a color depends on the specific device used to capture, display, or print the color. For example, a RGB color model represents a color as a mix of red, green, and blue primary colors. The final output color depends on how the ‘red’, ‘green’, and ‘blue’ colors are specified, which could vary between devices (e.g. – the ‘red’ defined by one computer monitor can differ from the ‘red’ defined by another).

Some examples of device-dependent color models include RGB (sRGB, Adobe RGB, etc.) and CMYK (depends on printing medium and ink colors).

Device-independent color model: A color model where a color is defined with reference to a standard illuminant and observer, often derived experimentally in laboratory conditions. The resulting color does not depend on a specific device (e.g. – camera, computer monitor, or printer).

Some examples of device-independent color models include CIEXYZ, CIELAB and CIELCH.

Multi-Point Averaging: Multi-point averaging is a technique in which multiple color measurements are taken at different points on a sample and the results are averaged to give a more accurate representation of the color. This technique is useful for measuring the color of textured or irregular surfaces, as well as for finding an average color for a surface with slight color variations.

Reference White: The reference white is the theoretical perfect white with respect to the standard illuminant and observer. For example, D50/2° stands for D50 illuminant and 2° observer, while D65/10° stands for D65 illuminant and 10° observer.

Note: The perceived color can change with the reference white point, and colors with difference reference white points cannot directly be compared. Two objects that appear to match under one illumination source and observer condition can appear to be mismatched under other (see ‘metamerism’)

Metamerism: Refers to the condition where two different colors are perceived to be identical under one set of conditions but mismatched under another. ‘Illuminant metamerism’ occurs when two objects reflect light differently, but in a way that both have the same perceived color under certain lighting conditions. This match is lost if the lighting condition is changed.

For example: two objects that appear to be color matched under ‘Illuminant A’ (indoor, incandescent lighting), may appear to be mismatched under ‘Illuminant D65’ (outdoor, daylight).

Color spaces & data types

Different “Color Spaces” have been defined to aide in the communication and representation of color. In this section we define the color spaces and how they are used.

CIEXYZ

Definition: CIEXYZ: CIEXYZ is a device-independent color model defined by the CIE. It was derived experimentally and describes all possible colors seen by average human color eyesight. Colors in the CIEXYZ space are defined by three color coordinates (X, Y, and Z) and are referenced to a specific reference illuminant and observer (the ‘reference white’ point). The Y value describes the luminance, while X and Z together define the ‘chromaticity’ or ‘quality’ of a color.

As a device-independent color model, CIEXYZ is used as the basis for other color models. The CIEXYZ value is often transformed to the CIELAB color space which is easier to manipulate and understand.

Usage: Database creation, mathematical calculation, scientific uses.

Notes:

- Typically never used directly by a customer. Usually only used in math.

- The base system for Nix Colorimeters

- Device independent

- Can represent all possible colors perceptible by humans

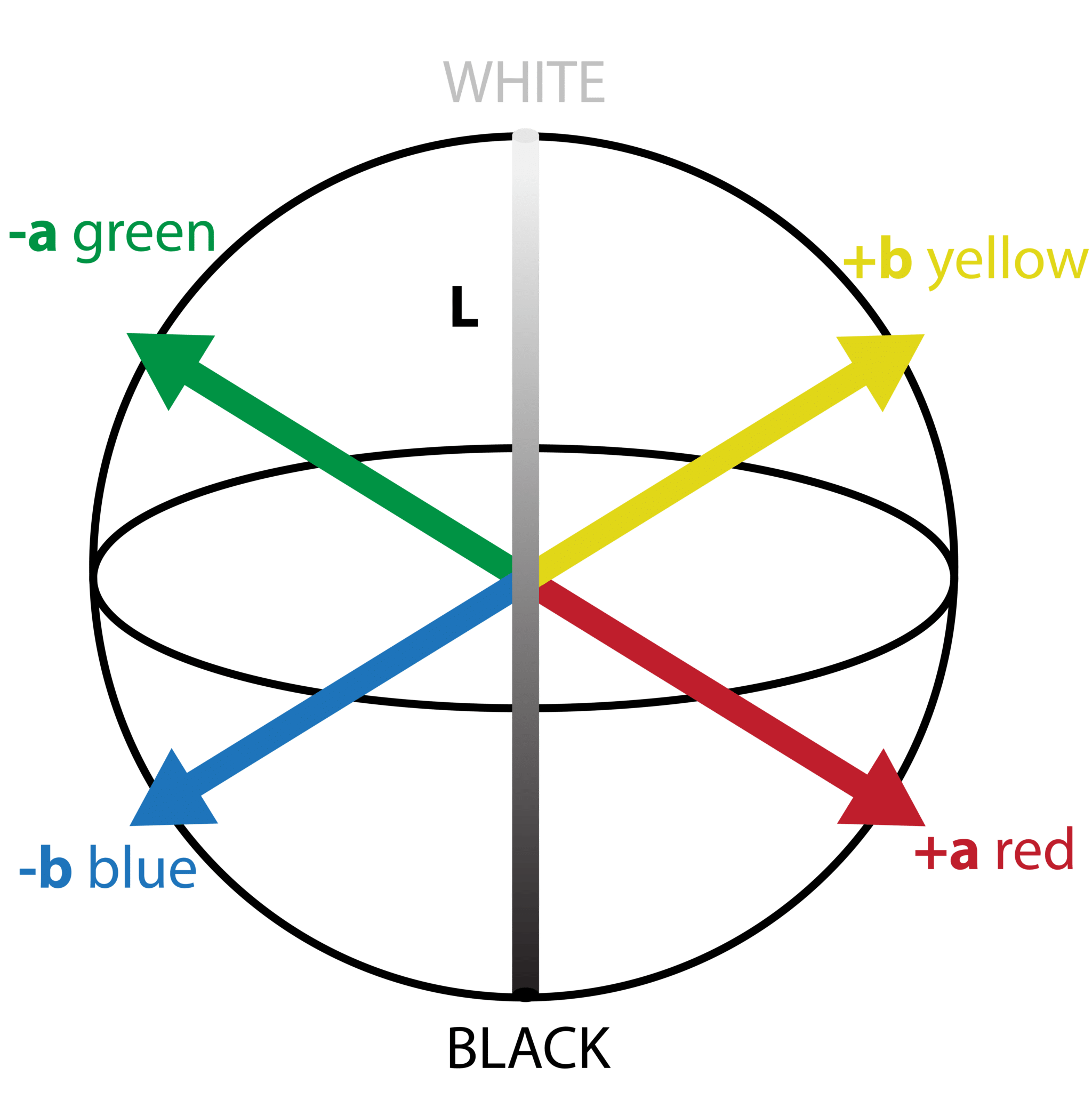

CIELAB

Definition: CIELAB is a color space that is used to describe color and is based on the human perception of colors. It is a three-dimensional color space that is used as a reference device-independent color model. CIELAB stands for L (lightness), A (green-red axis), and B (blue-yellow axis).

Usage: Database creation, Delta E calculations, scientific cataloguing.

Notes:

- Remapping of CIEXYZ for perceptual uniformity

- The backbone of the Nix database system

- Device independent

- Can represent all possible colors perceptible by humans

The Lab sphere is intended to be “perceptually uniform.”

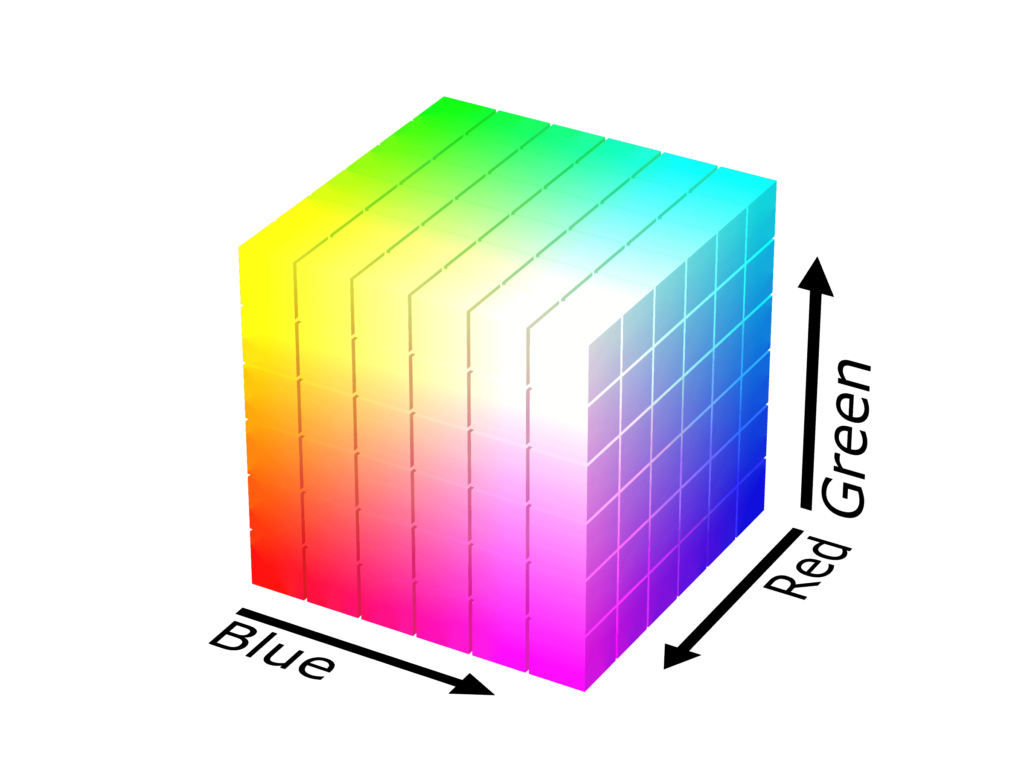

RGB

Definition: In the RGB color model, a color is created by varying the intensity of each of the three primary colors. By adjusting the intensity of the red, green, and blue light, a wide range of colors can be achieved. Each color in the RGB model is represented by three numerical values ranging from 0 to 255, which indicate the intensity of red, green, and blue light in the color in that order. For example, the RGB values for pure white are 255, 255, 255, and the RGB values for pure black are 0, 0, 0.

Usage: Monitors, digital photography, phone screens, TV, graphic design, web

Notes:

- Additive process

- Device dependent

- Limited gamut

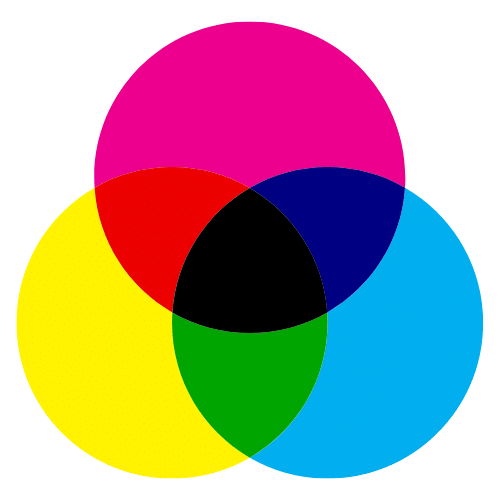

CMYK

Definition: In the CMYK color model, the primary colors are subtractive rather than additive, as in the RGB model. This means that when the colors are overlaid on top of each other, they subtract light instead of adding light, resulting in a darker color. Black is included as the fourth primary color to ensure deeper and richer tones, and to reduce the amount of ink used. Each color in the CMYK model is represented by a percentage value ranging from 0% to 100%, indicating the amount of that color used in the mixture. For example, 100% Cyan, 0% Magenta, 0% Yellow, and 0% Black will result in a pure cyan color.

Usage: Specifies ink formulation for print and packaging

Notes:

- Subtractive process

- Not standardized.

- Depends heavily on process, inks, substrate material etc.

- Sometimes augmented with extra “spot colors” ex. CMYK + “Home Depot Orange”

- Limited gamut

CMYK is a subtractive color system

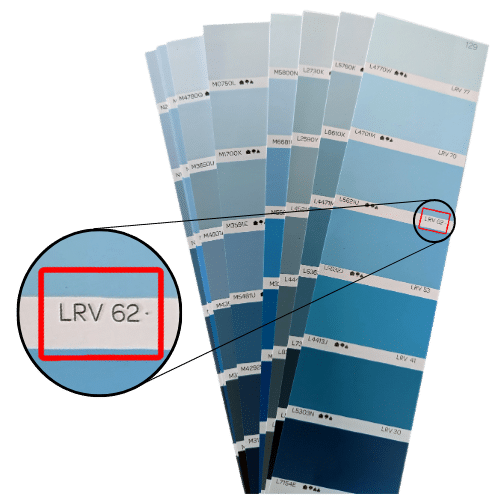

LRV

Definition: Light reflectance value. Measured on a scale of 0-100. 0 being absolute black and 100 being absolute white.

Usage: Interior designers, engineers, architects use to determine the relative brightness of a color irrespective of the hue. This is useful for estimating how bright a paint will look in a room for example.

Notes:

- Can be mandatory for certain regulations. Ex. Steps or ledges, signs, etc. must have a certain LRV contrast ratio to allow people to see the edge.

- Can be useful for engineers to determine the number of windows and lights needed in a space.

The LRV of sample blue paint colors are shown.

HSV & HSL

Definition:

- HSL: Hue (angle), Saturation, Lightness

- HSV: Hue (angle), Saturation, Value

Usage: Used for artistic purposes and to help visualize changes in color vs brightness.

Notes:

- Helps to model the way different paints mix together to create color in the real world.

Performance terminology

Repeatability: the measured ability of one instrument to deliver same/similar output results, in Delta E while being tested repeatedly under the same measurement conditions. The lower the deviation the more consistent the device is considered to be

Inter-Instrument Agreement (IIA): The difference in output measured in Delta E between 2 devices of the same model. The lower the deviation the more similar the output and the higher performance of the device.

Intra-Instrument Agreement: The difference in output measured in Delta E between 2 devices of the differing models or manufacturers. The lower the deviation the more similar the output and the higher performance of the device.

Calibration: Calibration is the comparison of measurement values delivered by a device under test with those of a reference standard of known accuracy. Factory calibration is a process that is undertaken with each Nix device before it is shipped to ensure that the device operates within known tolerances. This ensures output that is consistent with other copies of the same device model.

Delta E: Delta E measures the difference between two colors. A Delta E value of zero indicates a perfect match, while high Delta E levels indicate a significant mismatch. The Delta E value that represents a just noticeable difference (JND) depends on the specific use case, but a general rule of thumb is that JND is approximately 2 to 3. In other words: if the Delta E value is less than two, then the colors are not perceivably different.

Just Noticeable Difference (JND): JND measures the amount that something must be changed for a difference to be perceived. In the context of color theory, this corresponds to the Delta E level before two colors are noticeably different to human color vision.

Delta E (CIE2000): An improved formula for calculating Delta E, specified by the CIE in 2000. It was found that the CIE94 formula did not fully solve the non-uniformity issues in the CIELAB space. This more comprehensive formula revises the 1994 definition with additional corrections lightness, chroma, and hue. This is the latest and recommended option for use in Nix software.

Delta E (CIE76): A formula for calculating color difference of two color samples in the CIELAB color space, specified by the CIE in 1976. This value represents the distance between two color values in this three-dimensional color space. This formula has been replaced by later formulas to correct for non-uniformities in the CIELAB color space. Although it has been superseded, the CIE76 formula is still sometimes used due to its simplicity and ease of use.

Delta E (CIE94): An improved formula for calculating Delta E, specified by the CIE in 1994. The original CIE76 formula rates some color regions too highly (for example, highly saturated colors). This formula enhances the CIE76 formula by weighting differences in lightness, chroma, and hue differently. These weights can be different depending on the industry. For example, there are specific weights recommended for graphic arts applications which differ from those for textiles. This equation was later replaced by the CIE2000 formula.

Delta E (CIE94G): In Nix software, the Delta E (CIE94G) formula implements the Delta E (CIE94) equation using weighting factors recommended for graphic arts applications.

Delta E (CIE94T): In Nix software, the Delta E (CIE94T) formula implements the Delta E (CIE94) equation using weighting factors recommended for textiles.

Delta E (CMC l:c): An alternative formula for calculating color difference, specified in 1984 by the CMC. This formula calculates color difference based on differences in lightness, chroma, and hue. This equation allows the assignment of weighting factors, depending on the importance on lightness ‘l’ and chroma ‘c’ differences.

Delta E (CMC2:1): In Nix software, Delta E (CMC 2:1) implements the CMC l:c formula with ‘l:c’ values set to 2:1. This is commonly referred to as the threshold of ‘acceptability’.

Delta E (CMC1:1): In Nix software, Delta E (CMC 1:1) implements the CMC l:c formula with ‘l:c’ values set to 1:1. This is commonly referred to as the threshold of ‘imperceptibility’.

Delta-E Marginal: A measurement of color difference that is still acceptable, but is at the limit and may not always be the best option for the specific application. This value is considered the borderline between acceptable and unacceptable color difference.

Delta-E Pass: A measurement of acceptable color difference deemed acceptable in specific industries or applications. In other words, if a color falls within the Delta E pass range, it is considered usable without corrective action.

Delta E Type: Refers to the formula used to calculate a Delta E value. In Nix software, this is one of: CIE76, CIE94G, CIE94T, CIE2000, CMC2:1, or CMC1:1.

Delta E – Scan: The calculation of the Delta E between the scanned sample and the target standard color in QC applications.

QC Threshold: The amount of color difference that is considered acceptable or not noticeable. It is used to determine whether a color difference between two samples is significant and whether the difference needs correction. The threshold can vary depending on the industry and the project requirements. For example, a graphic designer may set a lower Delta E threshold for a product advertisement than for a billboard with a greater viewing distance. In the Nix Toolkit app, two values can be set: ‘pass’ and ‘marginal’.

QC Pass: A measurement of acceptable color difference set by the target threshold.

QC Marginal: A measurement of color difference that is still acceptable but nearing the acceptable limit. This value is considered the borderline between acceptable and unacceptable color differences.

Standard illuminants, observers, and measurement modes

The illuminant is the light source used to view or measure an object’s color

Remember: The perceived color of an object varies greatly with the illuminant. For best results you should ensure that your selected illuminant is consistent with your environment and consistent across your workflow.

Some common illuminants:

Illuminant A: Intended to represent typical, tungsten-filament lighting.

Illuminant C: Daylight simulation, representative of average day light.

Illuminant series D: Intended to represent natural daylight at various times of day. D50 (‘horizon light’) and D65 (‘noon daylight’) are the most used

Illuminant series F: Intended to represent common fluorescent lighting, such as those found in offices, retail locations and more.

Standard Observer: Defines a color mapping function that represents the average human’s color vision. These functions were derived experimentally in color matching experiments. The cells responsible for color vision are concentrated in the centre of field of view, so the experiments used to create these curves specify a field of view to which they apply.

2 degree: The 2° standard observer functions were defined by the CIE in 1931. These functions were based on color matching experiments focused on the centre of the field-of-view. This was based upon belief at the time that the color-sensitive cone cells were concentrated within a 2° arc on the fovea.

10 degree: The 10° standard observer functions were defined by the CIE in 1964 based on later experiments. These later experiments were conducted over a wider field of view.

Reflectance measurement conditions:

As defined in ISO 13655:2009 – Graphic technology — Spectral measurement and colorimetric computation for graphic arts images.

- M0: Legacy mode, Illuminant A (UV light below 420 nm is included in the light source. No longer recommended)

- M1: D50, UV-included mode (UV light below 420 nm is included in the light source. This is the recommended mode for most color measurement)

- M2: UV-excluded mode (UV light below 420 nm is filtered out from light source)

- M3: Polarizing mode (Unsupported by Nix devices)

Instrument geometry

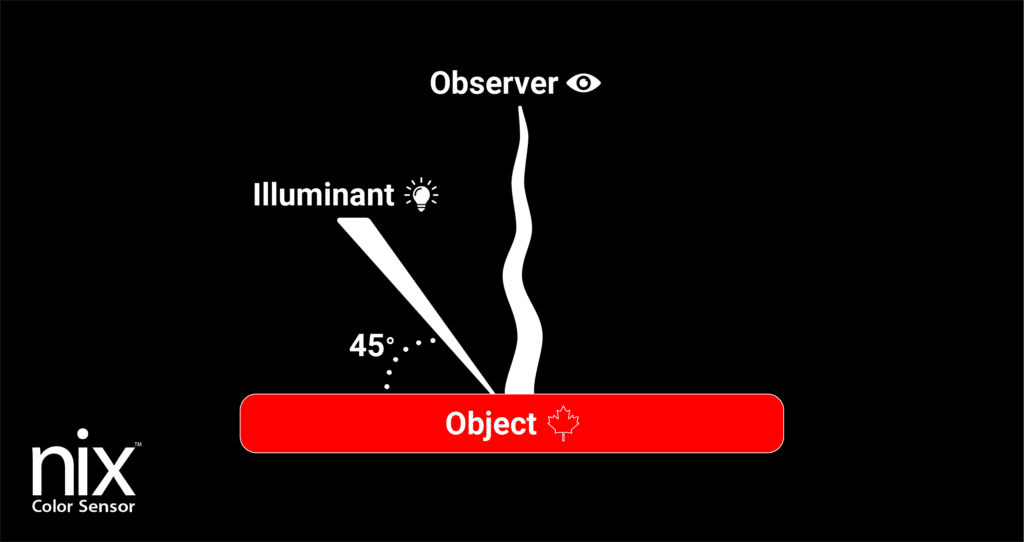

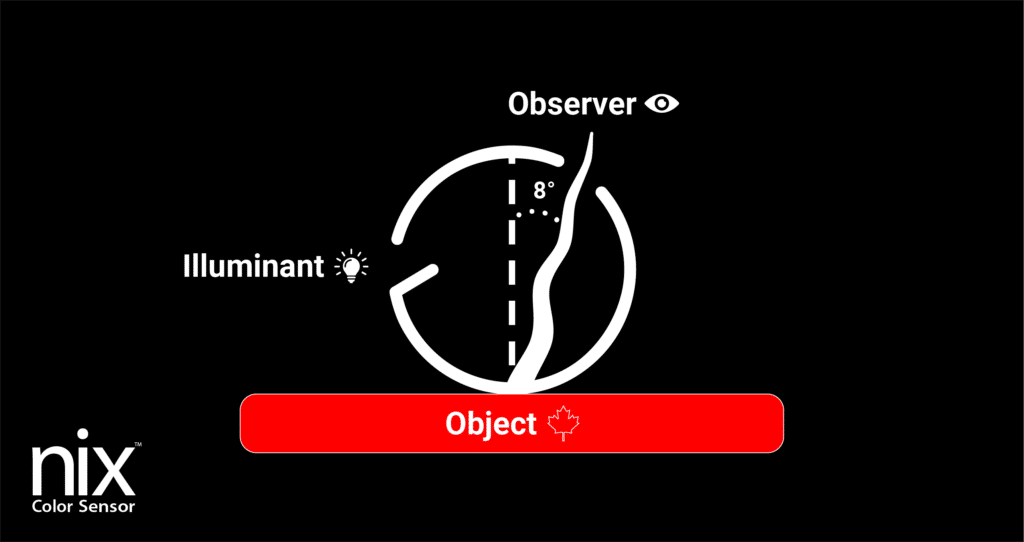

An instrument’s geometry refers to the physical arrangement of light source and sensor. The two main industry standards are:

45°:0°: The light source is set at a 45° angle to the surface of the object to be measured. The sensor is orientated directly down at the object (at a 0° angle). The 45° angle was standardized to mitigate the effects of surface finish and gloss of an object. All Nix devices created using this format in order to scan in harsher environments.

Spherical or D:8°: Spherical or diffuse 8° geometry employs the use of a white integrating sphere on the inside of the device. A diffuse light source is reflected off the sample surface and measured at an 8° angle to the normal. Spherical devices can measure using either specular included (SPIN, SCI) or specular excluded (SPEX, SCE) conditions. Spherical devices can be susceptible to deficient performance in dirty, dusty, and outdoor environments due to their open aperture and delicate components, which can be easily damaged and negatively impact the sensor’s performance.

Note: Changing between instrument geometries will drastically change the perceived color of an object and thus measurements between instruments of differing geometries should not be compared.